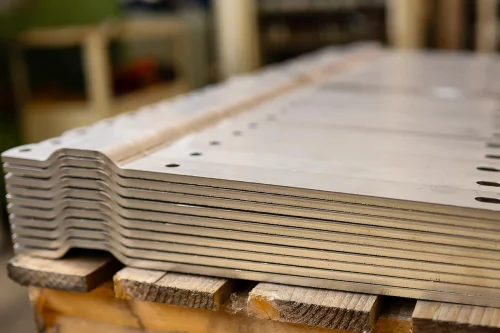

Specialized equipment for high-precision assembly

The assembly of inserts represents an essential step in the metalwork process. This operation consists of inserting and securing additional components, such as nuts and threaded and REM inserts, within metal structures so as to create strong and secure connections.

Thanks to our specialized equipment and the experience of our staff, we are able to perform the assembly with high precision, meeting strict quality standards.

We use state-of-the-art equipment for positioning and fixing inserts and REMs, which allow precise control and reduced errors.

The FXT team of qualified technicians performs each operation with attention to detail and rigor, ensuring that each insert is installed according to project specifications. This process helps to strengthen the structural quality of our products and meet our customers' needs with maximum reliability.

Do you want to know more?

Contact us without obligation