High-precision processing

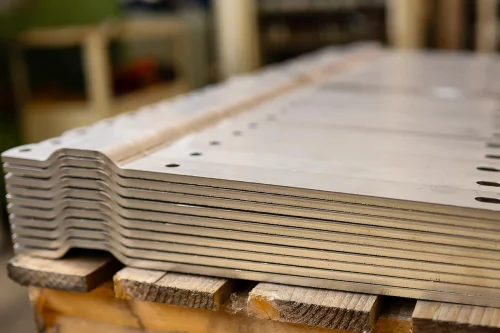

The process of plate calendering and edging begins with the treatment of laser-cut plates. After cutting, the semi-finished products are automatically calendered and welded under the welding bar.

If project specifications require further processing, the product is sent to our edging facilities. Here, we add ribs and crimps to reinforce and tailor the component to the needs of the project. This process allows us to achieve complex shapes and structures with high precision.

Our modern calendering and beading machines are designed to turn sheet metal into complex tubes and profiles, with a capacity to process up to 560 mm in diameter and thicknesses up to 3 mm.

We also offer in-house tooling services that allow us to further customize productions according to customer specifications. This combination of advanced equipment and specialized expertise enables us to produce highly adaptable, high-quality components, thus meeting a wide range of technical and design requirements.

They are also available in-house.

Do you want to know more?

Contact us without obligation