sheet metal working processes

10 December, 2024The main advantage of sheet metal calendering is that it is possible to obtain tubes of the desired diameter/thickness or complex curved components, of homogeneous thickness and with an accurate finish.

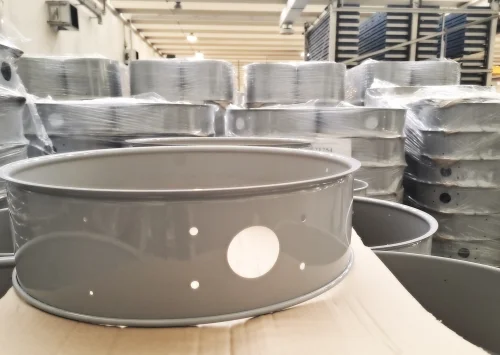

Calendering and sheet metal processing

F.X.T, S.p.A. is equipped to carry out this process on iron or stainless steel sheets with three or four roller machinery

tubes with diameter >Ø150mm with sheet metal thicknesses that can vary from min 0.8 mm to max 10mm

The Edging

Edging is essential to improve structural strength, eliminate sharp edges and prepare pieces for assembly.

Our machinery, with the aid of equipment designed and manufactured internally, can carry out customized sheet metal processing such as: trimming, ribbing, edging, curling and flanging on deep-drawn or calendered parts of all shapes.

Edging for diameters between Ø180mm and Ø560mm with sheet metal thicknesses that can vary from min 0.8mm to max 3mm">Calendering

The calendering of metal sheets is a particular mechanical process that allows the sheets to be bent in a homogeneous and uniform way to obtain pipes, flanges, tanks, complex curved components, ferrules.

The calendering of metal sheets occurs cold using machinery equipped with rollers that rotate, compressing the sheet metal. These rollers are placed at the vertices of an isosceles triangle: parallel to each other if you want to give a cylindrical shape, not parallel for a conical shape. Depending on the semi-finished product that needs to be produced, different curvature radii can be set, more or less narrow.

The main advantage of sheet metal calendering is that it is possible to obtain tubes of the desired diameter/thickness or complex curved components, of homogeneous thickness and with an accurate finish.

Calendering and sheet metal processing

F.X.T, S.p.A. is equipped to carry out this process on iron or stainless steel sheets with three or four roller machinery

tubes with diameter >Ø150mm with sheet metal thicknesses that can vary from min 0.8 mm to max 10mm

The Edging

Edging is essential to improve structural strength, eliminate sharp edges and prepare pieces for assembly.

Our machinery, with the aid of equipment designed and manufactured internally, can carry out customized sheet metal processing such as: trimming, ribbing, edging, curling and flanging on deep-drawn or calendered parts of all shapes.

Edging for diameters between Ø180mm and Ø560mm with sheet metal thicknesses that can vary from min 0.8mm to max 3mm

Do you want to know more?

Contact us without obligation